Non-Woven Bags

Make your next journey pleasurable with us.

Non-Woven Fabric

Non-woven fabric is made from web structures, formed together by separate fibers, and molten plastic film. The film is then perforated by machines mechanically, thermally, and chemically making the porous sheets, having no weaving or knitting involved to convert fibers into yarn whatsoever.

The recycled fabric has a small percentage of oil-based materials used in non-woven fabrics and varies based on the strength required.

Making the majority of non-woven fabrics recyclable after use. Using proper treatment facilities, making non-woven a more environmental fabric to use.

Important in industries like hospitals, schools, nursing homes, luxury accommodations, where the product is disposed of and used most.

Non-woven fabric has great functionality benefits such as durability, absorbency, liquid repellence, resilience, stretch, softness, strength, flame-retardancy, wash-ability, cushioning, thermal insulation, acoustic insulation, filtration, use as a bacterial barrier and sterility.

Fabric properties are combined to create a suitable fabric for specific jobs to achieve a balance between product life and cost.

Fabrics mimic appearance, texture, strength, of the woven fabric, and can be bulky, as per the thickest padding. The combination of materials provides a spectrum of products. Diverse properties used or as the components of apparel, home furnishings, health care, engineering, industrial, and consumer goods.

The fabric is synthetic, geotextiles, and raw materials.

Polypropylene, known as PP, a recyclable thermoplastic, widely used in many products. Resistant to many chemicals, acids, and solvents.

Polyethylene/HDPE plastic Polymers are the easiest to recycle. Polyester/ PET has two ways to recycle it chemically or mechanically, washing plastic bottles then shredding them plastic back to polyester chips putting them through a fiber making process.

PET is a polymer that is a long chain of repeating molecular units most common variety is polyethylene terephthalate PET plastic derived from crude oil to make plastic bottles. The raw materials are geosynthetic, which are both biodegradable and non-biodegradable, depending on their raw materials.

New repeatedly recycle procedure for Polyester has just been discovered in Hong Kong 8/2019 attached link:

https://www.eco-business.com/news/a-way-to-repeatedly-recycle-polyester-has-just-been-discovered/

Woven vs Non-Woven Fabric

Woven bags are reusable and recyclable. However, it takes more energy to make them, in turn, making them less environmentally friendly. Although new technology and automation machines are slowly increasing their energy efficiency, they still are not the most environmentally friendly bags available on the market. However, non-woven bags were firstly manufactured in China and from spun-bond non-woven polypropylene (PP) cloth. This material looks feels like cloth, but it doesn’t need to be woven, making them a far better choice when it comes to our environment and planet. The main benefits and features of using this material:

100% recyclable

Bio-degradable and can burn without toxic contaminants

No PVC coating or water used in the manufacturing process

More durability means they are more reusable

Screen printing and heat transfer full-color printing available

Competitive pricing

Lightweight

Strong

Pack-able or fold-able

Liquid repellent

Washable

Air-permeable

The list is endless

Non-woven bags used by a wide range of businesses today. Grocers stores, department stores, gift shops, bottle shops, promotional companies, and many more.Non-woven bags are one of the most environmentally friendly bags in the market place today. They have great versatile, strength and practicality.

Trending now

Trends Now :

The repercussions of using plastic bags are well-known worldwide, they are solid waste, pollutants that remain in landfills waste sites, as well as clogging drains, and filling our oceans, this is an epidemic worldwide.

Many companies, individuals, are reverting to the recyclable paper bag. There are limitations in this recycling process with paper, as we can only implement this a few times. Some paper bags are not reusable, and the recycling process goes on.

Unfortunately, cutting down trees is inevitable to make paper, which threatens the planet’s future and air quality. However, at Fantec Bags, we always prefer to make our paper bags out of the recycled paper pulp, even though we still use virgin pulp, thus reducing deforesting, as the paper is also a great choice, as its bio-degradable. We also use virgin pulp from sustainable forestry management to help support our environment.

Please see our Non Woven Bags below, with the different surface finishes, handles, printing,sewing and ultra-sonic bonding techniques.

When it comes to Non-Woven Bags, there exist a lot of diversity. One can use a lot of different handles, surface finishes, pp lamination, and with different printing techniques.

We can customize the bag to suit your needs.

Different color handles and fabric.

We can even print on the handles, or laminate them.

Different surface finishes and printing.

Different thickness of fabric gsm, for strength.

Hand sewing.

Ultra-sonic hot sealing.

Customize sides with tubing, different color tubing, no tubing.

Side walls can come in different widths, on no walls.

If you are interested in Non-Woven Bags to promote your own business, or to get a sample made, email [email protected] for information and price.

Our Range of Non-Woven Bags.

Non-Woven bags are strong and durable, act as a billboard for your branding image.

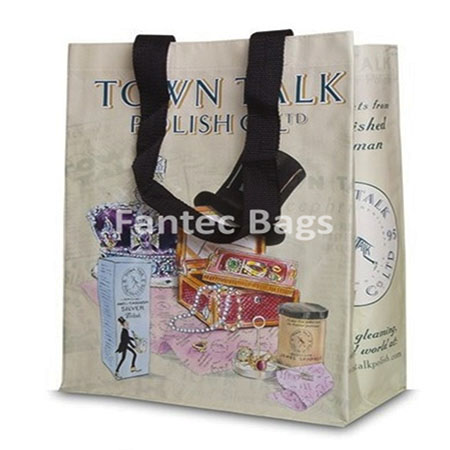

Non-Woven Bag. With Glossy PP Laminated, and Flat Cotton Handles.

This non-woven bag has flat cotton handles, giving an upscale feel and look. The handles are very strong, comfortable when carrying heavier loads.

This bag is finished with a glossy PP laminate print film finish, making it very appealing and vibrant. This whole bag has been sewn, with tubing on the outer side edges, X stitching on the handles for extra strength, and the non-woven fabric is 100 gsm.

Fantec bags can customize the bag to suit your needs.

Non-Woven Bag. With Glossy PP Laminated, and Flat Cotton Handles.

This non-woven bag has flat cotton handles, giving an upscale feel and look. The handles are very strong, comfortable when carrying heavier loads.

This bag is finished with a glossy PP laminate print film finish, making it very appealing and vibrant. This whole bag has been sewn, with tubing on the outer side edges, X stitching on the handles for extra strength, and the non-woven fabric is 100 gsm.

Fantec bags can customize the bag to suit your needs.

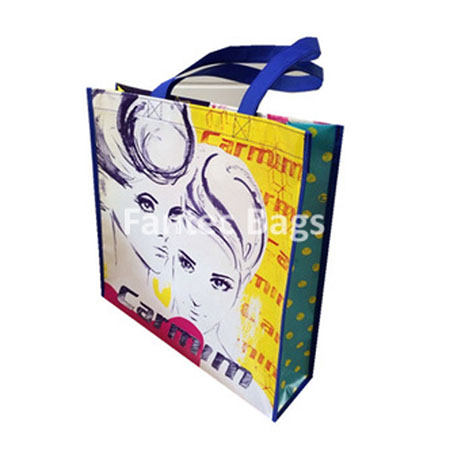

Non-Woven Bag. With Glossy PP Laminated, and Flat Cotton Handles.

This non-woven bag has flat cotton handles, giving an upscale feel and look. The handles are very strong, comfortable when carrying heavier loads.

This bag is finished with a glossy PP laminate print film finish, making it very appealing and vibrant. This whole bag has been sewn, with tubing on the outer side edges, X stitching on the handles for extra strength, and the non-woven fabric is 100 gsm.

Fantec bags can customize the bag to suit your needs.

Non-Woven Bag. With Matt PP Laminated, and Flat Polyester Handles.

Polyester handles also provide a similar feel as the cotton handles, but not quite as gentle as the cotton handles, especially under load. However, the polyester rope handles have far more strength than the cotton handles, and better when it comes to carrying heavier loads. There is a wide range of handles and colors to choose from for your bags. You can customize the handles further by printing your logo on them.

Non-Woven Bag. With Matt PP Laminated Finish, and Flat Cotton Handles. X stitching on the handles for extra strength.

This non-woven bag has flat cotton handles, giving an upscale feel and look. The handles are very strong, comfortable when carrying heavier loads.

This bag is finished with a glossy PP laminate print film finish, making it very appealing and vibrant. This whole bag has been sewn, with tubing on the outer side edges, X stitching on the handles for extra strength, and the non-woven fabric is 100 gsm.

Fantec bags can customize the bag to suit your needs.

Non-Woven Bag. With Glossy PP Lamination and Flat handles finished the same as the bag material and standard straight edge sewing.

This Non-Woven bag has flat handles, made with the same Glossy PP Laminate material as the bag. However, the handles are still very strong but do not feel comfortable as cotton handles and not as strong. This bag is finished with a glossy PP laminate print film, thus making it very appealing and vibrant. This whole bag has been sewn, with tubing on the outer side edges and straight stitching on the handles. The non-woven fabric is 100 gsm.

Fantec bags can customize the bag to suit your needs.

Non-Woven Wine Bag. With Glossy PP Lamination and Flat handles finished the same as the bag material and standard straight edge sewing.

This Non-Woven bag has flat handles, made with the same Glossy PP Laminate material as the bag. However, the handles are still very strong but do not feel comfortable as cotton handles and not as strong. This bag is finished with a glossy PP laminate print film, thus making it very appealing and vibrant. This whole bag has been sewn, with tubing on the outer side edges and straight stitching on the handles. The non-woven fabric is 100 gsm.

Fantec bags can customize the bag to suit your needs.

Non-Woven Wine Bag. With a Matt Finish and Flat handles finished the same as the bag material. X Stitching on the handles for extra strength.

This Non-Woven bag is in a matt finish. The material of the handle is the same as the bag, which provides a great feel making them strong and durable.

They can carry heavy loads, and we recommend X stitching, where the handles join to the bag for extra strength, especially carrying wine bottles. There is a wide range of handles and colors to choose from for your bags. You can customize the handles further by printing your logo on them

Non-Woven Wine Bag. With a Matt Finish and Flat handles finished the same as the bag material. With straight stitching on the handles.

This Non-Woven bag is in a matt finish. The material of the handle is the same as the bag, which provides a great feel making them strong and durable.

They can carry heavy loads, and we recommend X stitching, where the handles join to the bag for extra strength, especially carrying wine bottles. However, this bag has straight stitching only, which is quite strong, but X stitching is more preferred for wine bottles. There is a wide range of handles and colors to choose from for your bags. You can customize the handles further by printing your logo on them.

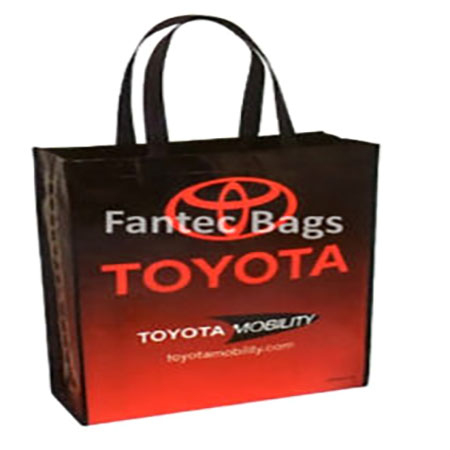

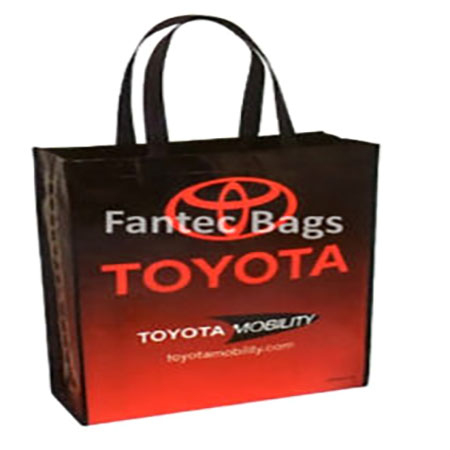

Non-Woven Bag with PP Lamination and the same material handles as the Bag. X stitching on the handles for extra strength.

This Non-Woven bag has flat handles, made with the same PP Laminate material as the bag. However, the handles are still very strong but do not feel comfortable as cotton handles, nor as strong. This bag is finished with PP laminate print film, thus making it very appealing and vibrant. This whole bag has been sewn, with tubing on the outer side edges and X stitching on the handles, adding extra strength. The non-woven fabric is 100 gsm.

Fantec bags can customize the bag to suit your needs.There is a wide range of handles and colors to choose from for your bags. You can customize the handles further by printing your logo on them.

Heavy Duty Non Woven Bag

Our Heavy Duty Non-Woven bag with PP Laminated Handles, provides a nice feel to the handles, and they are quite strong durable. They can carry heavy loads, even with the standard stitching or sewing.

However, the heavy-duty bags are wider and have extra handle length, with an upper-body band for extra support, made from the same material as the bag, giving extra strength for heavier loads.

Where the X stitching on the handles joins them onto the tote bag, giving it strength. Fantec bag handles are available in different colors, and one can customize them further by printing them.

Non-Woven Bag with NO PP Laminated, with the same material for the handles, the bag has X stitching on the handles for extra strength.

Non-Woven bag, with NO PP Lamination, using handles made from the same material as the bag. Giving the handles a soft feel, yet, strong and durable.

The bags can carry heavy loads, even with standard stitching or sewing. However, X stitching on handles, where it joins to the tote bag, gives extra strength. Fantec bags and handles are available in different colors, and one can also customize them further by printing them.

Non-Woven Bag with PP Laminated, without lamination on the handles, however, X stitching on the handles for extra strength.

Non-Woven bag with PP Lamination, but with no lamination on the handles, provides a softer feel, they are quite strong and durable. They carry heavy loads, even with the standard stitching or sewing.

However, with X stitching on the handle, joined onto the tote bag, it will give it that extra strength.

Fantec bags and handles are available in different colors, and one can also customize them further by printing them.

Ultrasonic Heat Sealed Non-Woven Bag, with the same Material, Handles as the Bag.

This Non-Woven bag is known as hot sealed or ultrasonic heat sealing which, is the most cost-efficient way and the most commonly used procedure. The bags are lower in cost, as made by automation machinery, compared to the sewn Non-Woven Bags. The handles are generally the same as the bag, making them quite durable and comfortable.

Please watch our video on the Ultrasonic bag process.

Ultrasonic Heat Sealed Non-Woven Bag, with the same Material, Handles as the Bag.

This Non-Woven bag is known as hot sealed or ultrasonic heat sealing which, is the most cost-efficient way and the most commonly used procedure. The bags are lower in cost, as made by automation machinery, compared to the sewn Non-Woven Bags. The handles are generally the same as the bag, making them quite durable and comfortable.

Please watch our video on the Ultrasonic bag process.

RPET Non-Woven Bags.

RPET Non-Woven bags, made from Recycled PET plastic bottles. They are just as strong as the non-woven fabric.

The fabric looks similar, other than pattern, making the bags the same as non- woven bags, other than the procedure in which we make the RPET fabric. Please see our RPET fabric description below.

Non-Woven Bag, with PP Laminated, the same Material Handles as the Bag and X Stitching on the Handles for Extra Strength.

Non Woven bag with PP Laminated Handles provides the a great feel, they are quite strong and durable. They can carry heavy loads even with the standard stitching or sewing. However, with the X stitching on the handle where it is joined onto the tote bag will give it that extra re-assurance of strength. Fantec bags and handles are available in different colors, one can also customize them further by printing them.

RPET Non-Woven Bags.

RPET Non-Woven bags, made from Recycled PET plastic bottles. They are just as strong as the non-woven fabric.

The fabric looks similar, other than pattern, making the bags the same as non- woven bags, other than the procedure in which we make the RPET fabric. Please see our RPET fabric description below.

Standard-Non Woven Material.

Standard non-woven material, has perforated holes in it, like a diamond shape.

RPET Non-Woven Material.

RPET non-woven bag material is a square checked pattern and made from Recycled PET plastic bottles.

Our Non-Woven Bag, Printing, and PP Lamination Procedure.

What printing method we use at Fantec Bags for our Non-Woven Bags.

Non-Woven bags are a fantastic promotional tool, lot’s of companies use them as a gift or even sell them at the counter as a retail- able item, for the convenience of the customer. Others use them as a gift, at promotional sales events, seminars workshops, and now found to be in many retail stores.

With customized printing options available. To suit everyone’s needs when it comes to bags. We specialize in printing to increase your companies’ brand visibility in the eyes of the public. The bag is reusable over again, getting more exposure.

What printing method we use at Fantec Bags for our Non-Woven Bags.

Non-Woven bags are a fantastic promotional tool, lot’s of companies use them as a gift or even sell them at the counter as a retail- able item, for the convenience of the customer. Others use them as a gift, at promotional sales events, seminars workshops, and now found to be in many retail stores.

With customized printing options available. To suit everyone’s needs when it comes to bags. We specialize in printing to increase your companies’ brand visibility in the eyes of the public. The bag is reusable over again, getting more exposure.

There are a few types of printing processes applied to Non-Woven Bags:

Silkscreen printing the non-woven bags. This technique uses a stencil screen for each color to be applied, the screen is permeable in the design area, only allowing the paint to seep through to the substrate onto the non-woven fabric.

Watermarking brushes are named after waterborne elastomeric paste as printing medium. its common in textile printing and is also printed with clips. When printing, when printing mix the paste and water elastomeric. No chemicals or solvents are used in the washing process, which is worth washing with water. Its characteristics are good dying power, strong covering and fastness, water resistance, basically no odor. xxxxxxxx

A watermarking brush is used in textile printing and with clips. When printing, mix the paste and water elastomeric. No chemicals, solvents are used in the washing process with water. The characteristics are its drying power, coverage, water resistance, basically no odor, and it’s fast.

Heat transfer print is printing within printing. This method requires an intermediate medium. Printing pictures and texts on heat transfer film or paper, and transferring patterns on non-woven fabrics by warming up the transfer equipment.

Commonly used in textile printing, is heat transfer film. The advantages are high depth, patterns, and comparable photos.

It is suitable for small area color image printing. Its disadvantage is the price is high, and the printing cost is high.

Non-woven bags with PP lamination :

To make the bags classier and increase brand image, we suggest PP laminated on non-woven bag material. There are two types of PP lamination, gloss finish, and matt finish. Both types of bags widely used in the market today.

The gravure printing process consists of two steps. The traditional gravure printing process prints the pictures and texts onto the film. Now the patterned film is compounded on the non-woven fabric by the lamination process.

This printing method used in large-area color pattern non-woven bags. Its characteristics are exquisite printing, the whole process of machine printing, the printing cycle is short.

Also, the product has excellent waterproof performance, and the durability of the finished product is better than other printed non-woven bags. Having a longer life span, compared to the standard non-woven bags.

The disadvantage is that it conflicts with the concept of environmental protection because the composite film is difficult to degrade. But again, people tend to re-use it again and again due to its durable finish with great design. However, they last for a long time, reducing the multiple uses of plastic bag wastage. Also great for image, branding exposure.